Useful information

What you should know about prefab panel house delivery?

06.11.2020 09:15

The advantage of prefabricated panel element houses is the optimal balance between level speed of installation and efficiency of delivery. But when the distance from factory to building site is great every truckload matters. We lay out the most important things a house buyer should know about delivery and the most common mistakes to avoid.

Method of delivery limits the size of panels

Prefabricated panel element house delivery is usually done in the most common and therefore most available and cost effective mode – a standard tarpaulin covered articulated truck trailer. The inner dimensions of such a trailer measure at 13,6 m in length, 2,46 m in width and 2,65-2,8 m in height.

In almost all of the projects wall panel height is between 2,5 and 2,7 m in order to fit the trailer height. Non-standard higher panels require a higher trailer called a MEGA. As you know anything non-standard increases cost.

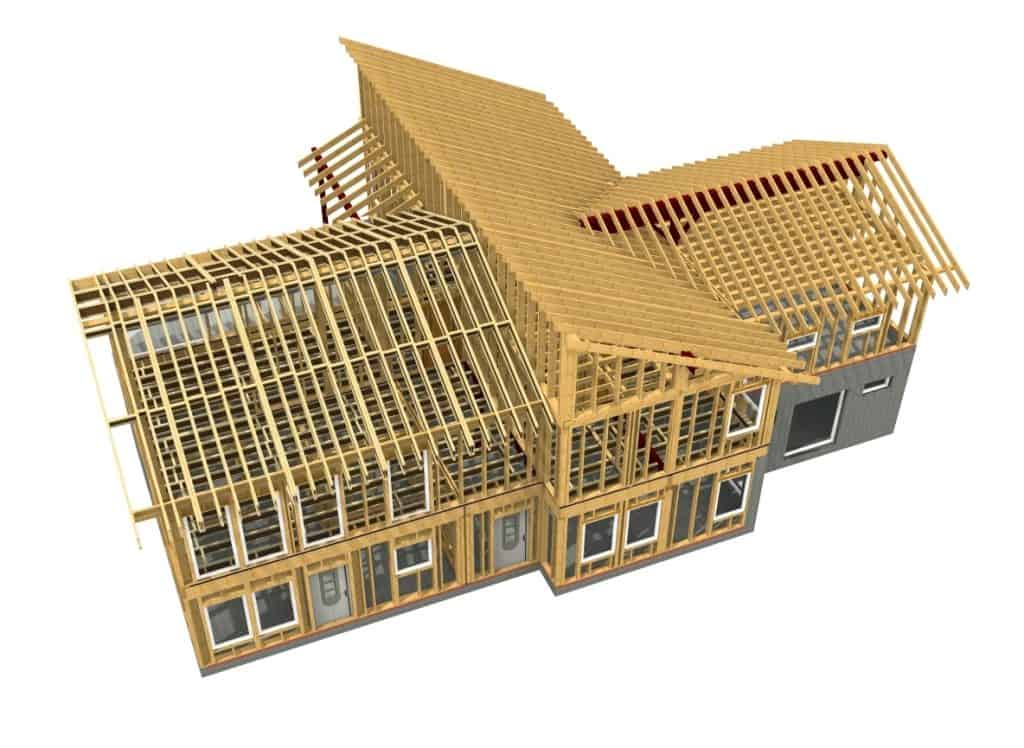

Panels are usually limited to 10 m in length so that they can be loaded in the trailer with a crane from the top. On the one hand the engineer preparing production drawings tries to make panels as long as possible to decrease the number of lifts during installation and seams and with that the time of installation, but also have to consider their layout in the trailer so that they can be delivered with a minimum number of trucks.

Consider space available on the building site

Delivery schedule depends on how work is organized on-site. Usually elements are delivered in a sequence to match the order of installation works on site to minimize handling and storing the elements after delivery.

In case there is no space for storage at all at the building site, installation of elements can be done directly from the truck. This requires meticulous planning and it means deliveries will not be filled optimally which probably will require more deliveries and hourly rate of idle time for trucks during unloading. Therefore it usually is better for the house buyer to arrange temporary storage space with the neighbouring lot.

When considering space on the building site one should also think about the possibilities for the crane to maneuver during unloading and installation.

The construction site must be accessible with an articulated truck

It is the responsibility of the buyer to make sure the construction site is accessible with a standard articulated truck. Narrow roads with sharp turns or bad dirt roads can be an obstacle. Such situations can be solved by planning a non-standard transport or reloading to a smaller transport but it will definitely mean extra costs which are covered by the buyer.

How many trucks are required for delivery?

The number of trucks required for delivery first and foremost depends on the size of the house. The bigger the house, the bigger the area of the elements and more volume in the trailers is required.

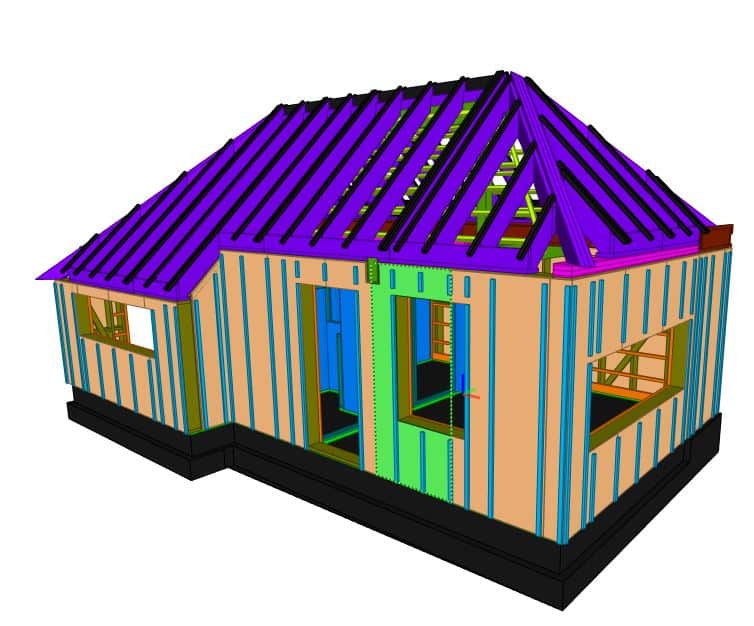

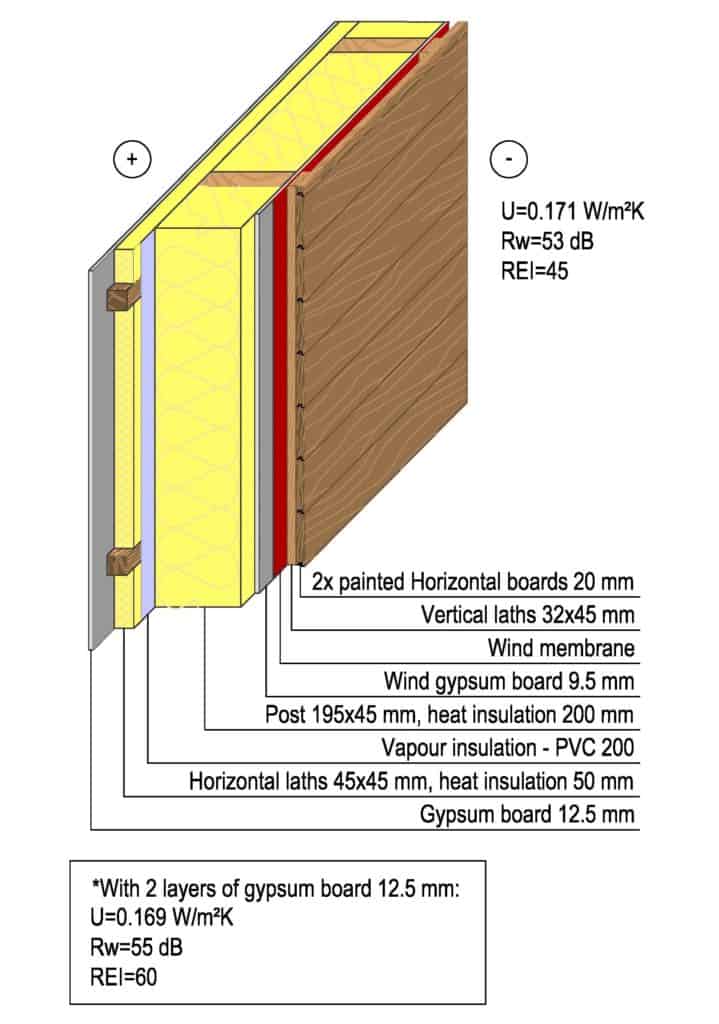

The second factor is the thickness of the elements. A more energy efficient house not only requires more material but also takes up more room in the trailer. The most common is the difference in the wall insulation layer between 195 mm and 245 mm which increases the thickness of the panel by about 15%. This difference can mean an extra truck for a typical single family house.

It also depends on the type of element delivered. Depending on the type of siding or simply the level of prefabrication required from the buyer, panel thickness can vary.

Buildings with complicated designs may require production of panles that are not optimal for delivery and therefore increase the number of trucks required.

As a rule of thumb a building kit for an outside finished house may require a truck for about every 30-40 m2 of floor. However this can vary a lot due to aforementioned reasons and in a price offer is always estimated looking at each project individually.

Cost of delivery

House manufacturers hire transport from logistics companies to ensure delivery of the building set. The cost of each transport unit depends foremost on the distance from the factory to the building site. Also deliveries to remote areas where transport companies cannot get a returning cargo may cost extra. The cost of delivery for a specific project is quoted in the price offer.

Summary

- Panels are delivered with a standard articulated truck trailer.

- The buyer must consider the space for unloading and ensure truck access without obstacles.

- Delivery costs for a specific project are quoted in the price offer.